In The Field

Built for Heat, Abrasion, and Continuous Duty

Asphalt plants punish components—high temps, abrasive aggregate, and nonstop cycles. Use purpose-built chain, sprockets, and wear protection.

Asphalt Plant Conveyor Challenges

Hot temperatures, heavy loads, and abrasive aggregates require purpose-built components to keep your plant running.

High Temperature Operation

Asphalt plants operate at extreme temperatures (up to 900°F) requiring specialized heat-resistant chains and components.

- Chain elongation from heat

- Premature wear and failure

- Lubrication breakdown

Heavy Aggregate Loads

Moving tons of hot aggregate and asphalt mix creates extreme stress on conveyor systems.

- Link and pin failures

- Sprocket tooth wear

- Structure fatigue

Abrasive Materials

Continuous exposure to abrasive aggregates accelerates wear on chains, sprockets, and wear surfaces.

- Rapid chain elongation

- Wear liner degradation

- Increased maintenance

Our Asphalt Plant Solutions

Heat-Treated Chains

Heat-treated alloy chains maintain strength and resist elongation at high temperatures.

- Temperature rated to 1000°F

- Minimal thermal expansion

- Extended service life

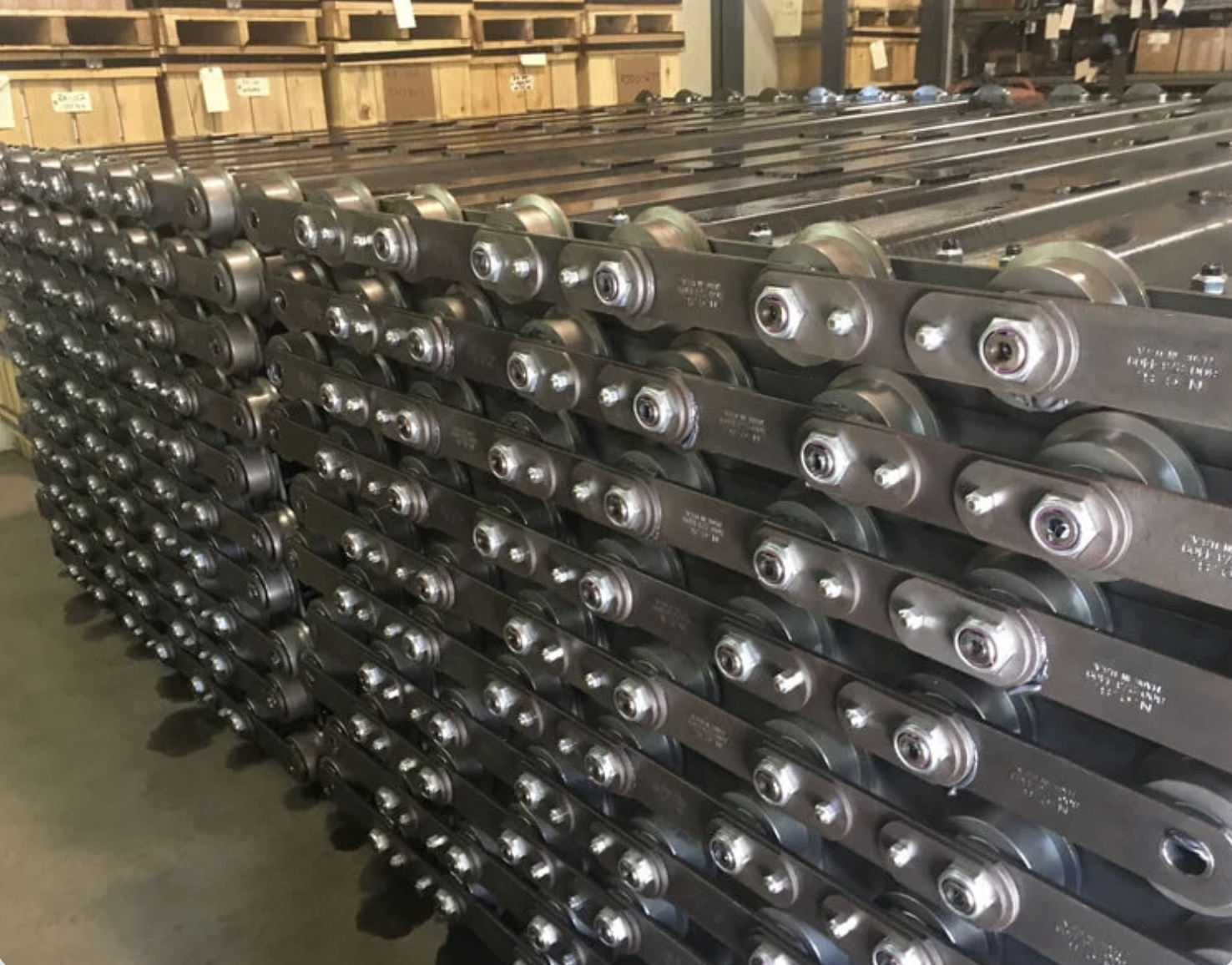

Heavy-Duty Sprockets

Hardened sprockets with optimized tooth profiles for asphalt plant applications.

- Wear-resistant materials

- Custom tooth geometry

- Split hub designs

Abrasion Protection

High-performance wear liners protect equipment from abrasive aggregate damage.

- AR400/AR500 steel liners

- Custom fit designs

- Easy replacement systems

Request an Asphalt Plant Quote

Share your plant type and requirements. We’ll respond within one business day.

Why Choose Klockner?

- Industry Expertise: Decades of experience in industrial solutions.

- Custom Solutions: Tailored to your unique operational needs.

- Unmatched Quality: Built to last with rigorous quality standards.

- Responsive Service: From emergency repairs to proactive maintenance.

Upgrade Your Asphalt Plant Conveyors

Industry-specific solutions designed for asphalt production.